Ich habe während 4 Monaten Erfahrungen mit der Braubox von Besserbrauer gesammelt. Dabei habe ich im Test ingesamt 3 unterschiedliche Biere gebraut (Pale Ale, Helles und IPA). Die Braubox ist in meinen Augen klar das beste Set um selber zu Hause Bier zu brauen und kann absolut empfohlen werden!

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Transparenz ist mir wichtig: Ich habe die Braubox selber gekauft und erhielt keinerlei kostenlose Produktproben von Besserbrauer. Wenn du jedoch etwas über meinen Link kaufst, erhalte ich (ohne zusätzliche Kosten für dich!) eine kleine Provision.

Was genau ist in der Braubox enthalten?

Wer sich für die Braubox von Besserbrauer entscheidet, enthält mit dieser unter anderem eine 5-Liter-Gärflasche aus Glas. Dazu gibt es eine Pumpe zum Abfüllen des Biers aus der Gärflasche, wobei hier auch ein Schlauch mitgeschickt wird.

Weiterhin befinden sich in der Braubox eine Schlauchklemme, eine Dosierhilfe und eine Brauanleitung. Darüber hinaus ist ein Zutatenpaket vorhanden, in welchem sich Braumalz, Hopfen und Hefe befinden.

Mit der Braubox wird also ein praktisches Gesamtpaket aller Utensilien und Zutaten geboten, welche zum Brauen in der heimischen Küche benötigt werden.

Für wen ist die Braubox geeignet?

Geeignet ist die Braubox natürlich für alle Bierliebhaber, welcher sich schon immer mal an dem Brauen versuchen wollten. Weiterhin eignet sich diese aber auch für Bierliebhaber, welche ihr Bier besonders nachhaltig genießen möchten und somit auf dem Kauf im Supermarkt verzichten möchten.

Nachhaltig ist die Braubox vor allem, da deren Utensilien hauptsächlich aus Glas bestehen. Große Mengen an Plastik lassen sich in dieser nicht vorfinden.

Da das Bier nach den eigenen Präferenzen gebraut wird, handelt es sich darüber hinaus um ein perfektes Set für alle Personen, welche ihr Bier genau nach ihrem Geschmack genießen möchten. Zu guter Letzt sind natürlich auch Personen gut mit der Braubox beraten, welche ihren Freunden ein ausgefallenes Geschenk machen möchten.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Was verspricht die Braubox?

Die Braubox verspricht vor allem Spaß, denn mit dieser wird das Brauen einfach gemacht, sodass sich die Braubox sowohl für Anfänger als auch für Fortgeschrittene der Braukunst eignet. Weiterhin verspricht die Braubox das frischeste Bier überhaupt:

Der Geschmack von keinem Supermarkt-Bier fällt so frisch aus wie von Bier, welches mit selbst gebraut wird. Darüber hinaus verspricht das Set zum Selbst-Brauen aber auch Nachhaltigkeit, denn der Kauf von Bier im Supermarkt ist somit nicht mehr notwendig.

Anleitung mit meinen Erfahrungen

Vorbereitung

Bevor mit Hilfe der Braubox mit dem Brauen des eigenen Bieres begonnen werden kann, müssen noch einige Vorbereitungen getroffen werden. Diese betreffen vor allem die richtigen Utensilien zum Brauen:

Neben der Braubox wird nämlich noch ein Kochtopf mit einem Volumen von 8 bis 10 Litern benötigt. Weiterhin werden ein Kochlöffel, ein Messbecher, ein großes grobmaschiges Küchensieb, ein Trichter, ein Teesieb sowie mehrere lehre und saubere Bierflaschen benötigt.

Sauberkeit ist beim Brauen das A und O. In unserem 3 Tests hatten wir zum Glück niemals Probleme mit Schimmel. Das liegt aber natürlich sicherlich auch daran, dass wir alle Utensilien immer sehr gut gereinigt haben. Unsere Erfahrungen haben gezeigt, dass mit der richtigen Vorbereitung und penibler Sauberkeit viele Probleme bei der Gärung verhindert werden können.

Nun kann mit dem Brauen begonnen werden:

Maischen

Wurden alle wichtigen Vorbereitungen getroffen, so wird mit dem Maischen begonnen. Es handelt sich hierbei um den Schritt, bei welchem der Zucker aus dem Malz gewonnen wird, denn dieser wird später zu Alkohol umgewandelt und bildet außerdem die Kohlensäure in dem selbstgebrauten Bier.

Für das Maischen wird ein Kochtopf auf dem Herd platziert und mit 4 Liter Wasser befüllt. Das Wasser wird nun auf eine Temperatur von 72 °C erhitzt.

Damit diese genau erreicht wird, wird das Thermometer aus dem Lieferumfang der Braubox verwendet. Das Malz aus dem Brauset wird nun in das 72 °C heiße Wasser eingerührt, wobei darauf geachtet werden sollte, dass keine Klumpen entstehen.

Durch die Zugabe von dem Malz sinkt die Temperatur nun leicht, was gewollt ist. Die Temperatur sollte sich nun über einen Zeitraum von 1 Stunde zwischen 65 und 69 °C befinden.

Nach 60 Minuten wird die Temperatur der Maische dann nochmal auf 78 °C erhitzt, woraufhin der Topf vom Herd genommen wird. Dieser Prozess wird als „Abmaischen“ bezeichnet und ist essenziell, damit sich auch tatsächlich eine möglichst große Menge an Zucker von dem Malz trennt.

Läutern mit der Braubox

Nun geht es direkt an das Läutern, bei welchem das Malz von der Flüssigkeit getrennt wird. Dieser Schritt ist unter anderem auch wichtig, um noch möglichst viel Zucker aus dem Malz auszuwaschen.

Für diesen wichtigen Schritt des Brauens werden das große grobmaschige Sieb, der Messbecher sowie ein Kochlöffel benötigt. Außerdem wird ein weiterer Topf zum Auffangen der Flüssigkeit benötigt.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Das große grobmaschige Sieb wird nun auf den Topf gelegt, sodass das Malz aus der Maische mit Hilfe des Kochlöffels in dieses gegeben werden kann. Wurde das gesamte Malz aus der Maische in das Sieb gegeben, so wird die Restflüssigkeit aus der Maische in das Sieb gegossen, sodass diese in den sich darunter befindenden Topf fließt.

Es sollte hier darauf geachtet werden, dass die Flüssigkeit langsam und gleichmäßig über das Malz aus der Maische läuft. Aus diesem Grund sollte für diesen Vorgang am besten der Messbecher aus der Braubox verwendet werden.

Ist die gesamte Flüssigkeit aus der Maische durch das Malz in dem Sieb gelaufen, so wird der erste Topf gereinigt und erneut mit 3 Litern Wasser befüllt, welche dann mit Hilfe des Thermometers auf eine Temperatur von 78 °C erhitzt werden. Bezeichnet wird dieser Vorgang auch als „Nachguss“.

Die 3 Liter Wasser werden nun über das Malz gegossen, welches sich in dem Sieb befindet. Dieser Schritt des notwendig, da sich in dem Malz immer noch große Mengen an Restzucker befinden.

So wird die Menge der Flüssigkeit, in welcher sich nun der Zucker aus dem Malz befindet, nochmals erhöht. Diese Flüssigkeit, welche nun den Malzzucker enthält, wird auch als „Würze“ bezeichnet und wird später zu dem Bier, welches selbstgebraut wird.

Zugabe der Hopfen

Im nächsten Schritt wird der Hopfen in die Würze gegeben. Dieser Schritt wird aus diesem Grund auch als „Hopfenkochen“ bezeichnet.

Für diesen Schritt werden grundsätzlich der Hopfen und die Dosierhilfe aus dem Brauset benötigt. Weiterhin werden die Würze in dem Kochtopf, ein Waschbecken, Leitungswasser, Eiswürfel oder Kühlelemente benötigt.

Als erstes wird die gesamte Hopfenmenge aus dem Set in 4 Portionen unterteilt. Nun wird die Würze, welche sich in dem Kochtopf befindet, zum Kochen gebracht, wobei darauf geachtet werden sollte, dass sich die Temperatur nur knapp über dem Siedepunkt befindet.

Nach 10 Minuten des Kochens wird nun die erste Portion des Hopfens in die kochende Würze gerührt. 50 Minuten nach dem Beginn des Kochens wird dann die zweite Portion des Hopfens in die Würze gerührt.

Wurde die Würze für insgesamt 60 Minuten gekocht, so wird diese vom Herd genommen und sofort in ein Eisbad in dem Waschbecken gestellt, damit diese schnell herunterkühlen kann. Es sollte nun mit dem Thermometer gemessen werden, bis die Temperatur der Würze auf 80 °C gefallen ist, bis die rechtlichen zwei Portionen Hopfen in diese gegeben werden.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Die restlichen Portionen des Hopfens sorgen nun für ein fruchtiges Aroma im Bier. Nun sollte gewartet werden, bis die Temperatur der Würze auf 25 °C gefallen ist.

Gärung

Mit der Gärung geht es nun an den wichtigen Schritt des Brauens. Bevor mit dieser jedoch begonnen werden kann, sollten die Gärflasche, der Gärstopfen und der Gärspund mit dem Reinigungsmittel aus der Braubox sterilisiert werden, denn kommen nicht-sterile Utensilien mit der Würze in den Kontakt, so kann das Brauen zu einem Desaster werden.

Nun wird ein Teesieb auf die Öffnung der Gärflasche gelegt, woraufhin die Würze in die Gärflasche gefüllt wird. Gefüllt werden sollte die Flasche bis zu ihrer Wölbung.

Stellt die Würze nicht genügend Flüssigkeit dar, um die Gärflasche bis zu ihrer Wölbung zu füllen, so kann einfach etwas Leitungswasser nachgefüllt werden. Damit das Bier nun gären kann, wird die Hefe aus der Braubox noch in die Gärflasche gegeben und durch ein kräftiges Schwenken der Gärflasche mit der Würze vermischt.

Nun sollte der Gärspund mit etwas Reinigungsmittel gefüllt werden, dann auf den Gärstopfen gesteckt werden und anschließend zusammen mit diesem auf die Gärflasche gesteckt werden. Der Gärspund sorgt zusammen mit dem Gärstopfen dafür, dass keine Luft in die Gärflasche gelangt, jedoch aus dieser entweichen kann.

Als letztes kommt es noch auf die richtige Lagerung von der Gärflasche mit ihrem Inhalt an: Diese sollte dunkel und bei Temperaturen von 18 bis 20 °C über einen Zeitraum von mindestens 1 Woche gelagert werden, wobei 10 Tage ideal sind.

Flaschenreifung

Für den letzten Schritt des Brauens werden die Bierpumpe mit Schlauch, die Schlauchklemme, die Dosierhilfe und das Reinigungsmittel aus der Braubox benötigt. Weiterhin wird ein Gefäß für die Reinigungsflüssigkeit benötigt, welches ein Fassungsvolumen von mindestens 3 Litern aufweist.

Zusätzlich werden noch Haushaltszucker, ein Trichter sowie 12 leere und sterile Bierflaschen mit 330 ml Fassungsvolumen benötigt. Zunächst wird nun ein gestrichener Löffel Zucker mit der kleinsten Portionseinheit aus der Braubox in jede Bierflasche gegeben. Bei den Bierflaschen haben wir im Test mit diesen hier gute Erfahrungen gesammelt.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Als nächstes wird der Schlauch über das obere Ende der Bierpumpe gezogen. Die Klemme wird wiederum an dem anderen Ende des Schlauches angebracht.

Die Bierpumpe sowie deren Schlauch sollten nun noch sterilisiert werden, wozu der untere Teil der Pumpe in Reinigungsflüssigkeit gehalten werden sollte, sodass der Schlauch einige Male mit dieser durchgespült werden kann.

Mehr zum Thema Reinigung findest du übrigens auf unserer Partnerseite flecken-entfernen.info. Insbesondere der Artikel „Flaschen reinigen“ sollte jeder Bierbrauer einmal gelesen haben.

Die Gärflasche sollte nun auf einem Tisch oder einer Küchenablage platziert werden und von ihrem Gärstopfen und Gärspund befreit werden. Die Bierflaschen werden wiederum an einer Stelle platziert, welche niedriger ist als die Stelle, an welcher sich die Gärflasche mit dem Jungbier befindet, denn so kann das Jungbier perfekt in die Bierflaschen gefüllt werden.

Als nächstes wird die Bierpumpe in die Gärflasche gesteckt, sodass das Jungbier in die erste Flasche gefüllt werden kann. Sobald die erste Flasche zu 90 % gefüllt wurde, wird die Klemme an dem unteren Ende des Schlauchs geschlossen, sodass kein weiteres Bier in die Bierflasche fließen kann – dieser Prozess wird nun bei jeder Bierflasche wiederholt, bis alle Flaschen vollständig gefüllt wurden.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Es sollte beim Befüllen der Bierflaschen grundsätzlich darauf geachtet werden, dass diese leicht schräg gehalten werden. Weiterhin sollte darauf geachtet werden, dass nicht zu viel Hefe vom Boden der Gärflasche aufgezogen wird und mit in die Bierflaschen gefüllt wird.

Die Bierflaschen sollten nun gut verschlossen werden und anschließend stehend für 3 Wochen bei 18 bis 20 °C gelagert werden. In dieser Zeit bildet sich die Kohlensäure in dem Bier und außerdem reift dieses noch etwas nach, sodass der perfekte Geschmack entsteht.

Nach 3 Wochen sollten die Bierflaschen dann in den Kühlschrank gestellt werden, wo diese bis zu 12 Wochen aufbewahrt werden können. Das Bier kann nun jederzeit genossen werden!

Etiketten für das Bier

Besserbrauer bietet selber noch keine Etiketten für das Bier an. Wir haben aber mit diesen Etiketten, welche für Tintenstrahldrucker geeignet sind, sehr gute Erfahrungen gemacht.

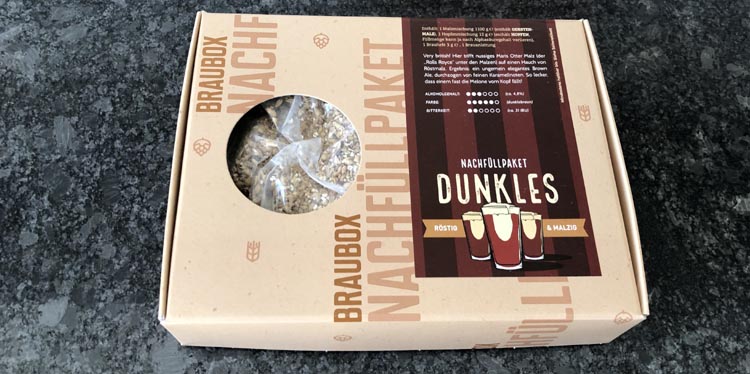

Nachfüllpakete die Braubox

Bei Nachfüllpaketen handelt es sich um Boxen, in welchen sich alle wichtigen Zutaten für den nächsten Brauvorgang mit der Braubox befinden. Dazu zählen Malz, Hopfen, Hefe sowie eine Brauanleitung.

Grundsätzlich bietet Besserbrauer verschiedene Nachfüllpakete für unterschiedliche Biersorten an:

Irish Extra Stout

Hierbei handelt es sich um ein Nachfüllpaket, welches zum Brauen der Biersorte Irish Extra Stout geeignet ist und somit unter anderem Aromen von Schokolade, getrockneten Pflaumen und Espresso enthält. Außerdem liegt der Alkoholgehalt hier bei 5,6 % und fällt damit etwas höher als bei anderen Biersorten aus.

Dunkles Weizen

Wer dunkles Weizen brauen möchte, ist mit diesem Nachfüllpaket gut beraten, denn in diesem sind die typischen Weißbier-Aromen wie Banane, Nelken, Aprikose und Karamellmalzen enthalten. Der Alkoholgehalt liegt hier bei 5,4 %.

India Pale Ale

Mit dem Nachfüllpaket India Pale Ale werden Aromen wie Orangenblüten, Aprikose und honigsüßes Malz mit einem typisch bitteren Hopfengeschmack kombiniert. Hier liegt der Alkoholgehalt bei 5,8 % und fällt damit ebenfalls etwas höher aus als bei anderen Biersorten.

Weizenbier

Wer frisches Weizenbier mit der Braubox brauen möchte, ist mit diesem Nachfüllpaket gut beraten. Der Alkoholgehalt liegt bei 5,5 %.

Pale Ale

Mit Pale Ale wird ein Nachfüllpaket angeboten, welches einen klassischen Geschmack bietet und das Aroma von Waldbeeren und Zitrusfrüchten enthält. Hier beträgt der Alkoholgehalt 5,6 %.

Helles

Natürlich kann auch Helles mit der Braubox gebraut werden, denn für diesen Zweck steht ein passendes Nachfüllpaket zur Verfügung. Der Alkoholgehalt beträgt hier 5,5 %.

Apfelcider

Wer Apfelcider einem Bier vorzieht, ist mit der Braubox ebenfalls gut beraten, denn auch für diesen Zweck steht ein entsprechendes Nachfüllpaket zur Verfügung. Der Alkoholgehalt liegt hier bei 4,5 %.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Treberbrot bzw. kann man mit dem Malz Brot backen?

Mit dem Malz ist es durchaus auch möglich, Brot zu backen, denn das Malz verfeinert zum einen das Aroma von dem Brot und sorgt zum anderen für einen perfekte Kruste. So gibt es zum Beispiel ein besonders simples Rezept, um mit einem Malztrunk Brot zu backen:

Benötigt werden dazu 500 g Mehl nach Geschmack, wobei sich zum Beispiel Weizenmehl, Roggenmehl, Dinkelmehl oder Vollkornmehl eignen. Weiterhin werden 1 Päckchen Trockenhefe, 1 Teelöffel Honig, 1 Teelöffel Salz, 1 Teelöffel einer Brotgewürzmischung, 1 Teelöffel Essig und 350 ml eines Malztrunks benötigt.

Zunächst wird nun ein Vorteig aus dem Honig, der Hefe, 1 Esslöffel Mehl und 1 Esslöffel Malztrunk zubereitet. Nach 5 Minuten Stehzeit werden nun das restliche Mehl, der Essig, das Salz und die Brotgewürzmischung hinzugegeben – von dem Malztrunk wird so viel dazugegeben, bis ein zäher Teig entsteht.

Nun wird der Teig eine geeignete Backform gefüllt, abgedeckt und 15 Minuten stehengelassen. Das Brot wird nun in den auf 200 °C vorgeheizten Ofen gegeben und zunächst noch mit dem restlichen Malztrunk und etwas Wasser eingepinselt.

Nach 60 Minuten Backzeit entsteht dadurch eine perfekte Kruste und das Malzbrot ist fertig.

Test-Fazit zur Braubox mit meinen Erfahrungen

Wer es sich mit dem Brauen einfach machen möchte und sich an diesem endlich einmal versuchen möchte, ist mit der Braubox bestens beraten. Diese bietet nämlich alle wichtigen Zutaten und Utensilien für das Brauen.

Außerdem macht die Braubox das Brauen möglichst simpel, sodass dieses schon beim ersten Durchgang ohne Fragen und Probleme ermöglicht wird. Darüber hinaus gibt es die verschiedensten Nachfüllpakete für die Braubox, sodass das Brauen der beliebtesten Biersorten möglich ist.

Letzte Aktualisierung: 23.04.2024 / * Werbelink / Bildquelle: Amazon

Des Weiteren bietet die Braubox einen hochwertigen Lieferumfang: Nicht nur die Utensilien sind aus hochwertigen Materialien gefertigt, sondern auch die Malzmischung, der Hopfen und die Hefe stammen aus einer qualitativ hochwertigen Produktion.

Zu guter Letzt wird die Braubox noch für einen fairen Preis angeboten, sodass sich das Brauen des eigenen Bieres auch finanziell lohnt.